How European manufacturers can face up to the competition from China

Over the past two decades, China has become an economic giant to be reckoned with. According to Karsten Bier, Ceo of the RECOM Group, manufacturers who assume that, for the foreseeable future, China will continue making only cheap products will be loosing out. He is convinced that China will soon grow into one of the top premium markets. He therefore is restructuring the RECOM Group to ensure that it can compete with Chinese manufacturers. In the long run, only global players that can face up to the challenge posed by Chinese manufacturer will be able to survive.

China will soon be the largest economy in the world. Incidentally, this is actually where China was before in the early 1800s. Due to the size of its workforce, China is ideally positioned as a manufacturer of mass-produced goods. As large quantities can generally be manufactured cheaper, this advantage will not be lost, even if salaries in China will reach western levels within the next ten or twenty years.

In the long term, China will remain the main competitor of European and US companies – without even considering controversial aspects such as scarce resources and rare minerals. How can European producers prepare themselves for these challenges? Karsten Bier is of the opinion that European manufacturers need to act fast and face the issue head-on by investing in China in order to establish their brands as a global premium brand. When selling products with a proven long service life to China, suppliers can now achieve better prices, and the trend is bound to continue.

This is true for RECOM’s large Chinese customers in the railway and energy sector who are already placing reliability before price. This also applies to the huge market for medical technical products. We must not forget that large Chinese corporations are focussing on their export business and want to shake off the image of poor product quality.

Advantages of Taiwan

When entering the Chinese market, RECOM benefited from the fact that the company had invested in development and production in the Chinese-speaking world some time ago. While labour costs in Taiwan are significantly higher than on mainland China, RECOM has been able to remain competitive by automating its production. As wages of qualified workers in China have been rising continually, the pressure on western manufacturers will decrease somewhat in the long term.

Fig. 2 – The two new production lines – A number of selected converters, such as the RECOM E-series can now be produced in batch sizes from 100,000 at significantly lower costs

In late 2012, RECOM commissioned two new SMT production lines, as the company had decided to integrate external capacities into its own production processes. A number of converter series can now be produced in large quantities at even lower prices, which is of particular advantage for high-runner series in the 2W range.

“With more than 20,000 different converter types, our product range is extremely broad,” explains Karsten Bier. However, high mix/low volume production still has its price. The company is time and again competing with manufacturers that produce large quantities of just a few converter types at extremely low prices, as focussing on few series keeps their tooling costs low. With its new production facilities, RECOM can now compete with these suppliers, as they are exclusively used for the production for high-runner series.

“We intend to move production of our high-runners in batch sizes of 100,000 and more to our own SMT plant.

We will then be able to offer these products to the global market at prices that are 25 to 35% below the current prices,” says Karsten Bier, emphasising that these units will be subject to the same stringent quality checks as all other RECOM products (RECOM gives a 3-year warranty on its voltage converters, while LED drivers come with warranties of 3 to 5 years).

Maximum automation instead of low wages

The US$ 3m investment in the new SMT production plant not only enabled the company to reduce its production costs as outlined above. Another major cost-cutting factor was the automation of the ring core production. Automatic winding, which had previously been deemed technically impossible, has put RECOM in the front seat and greatly improved quality control.

Thanks to these achievements, the company is now in a position to meet the demands of international key account customers who are looking for near-100% automation. Until recently, physical factors posed an obstacle for the automated winding of very small ring cores. Over more than three years, RECOM engineers worked hard in overcoming this issue. This great development success was achieved in close cooperation with a medium-sized machine manufacturer.

“We spent a substantial amount of money in developing this new technology,” says a proud Karsten Bier. In October 2012, the first special machine was installed at the plant in Kaohsiung, Taiwan – a milestone in the fully automated production of converters! The machine is able to wind even the tiniest cores with a bore diameter of as little as 2.5mm in a single, fully automated process. It is five to ten times faster than manual winding and all products are of the same high quality.

Fig. 4 – The quality of ring cores produced in a fully automated process is significantly higher than that of manually wound transformers

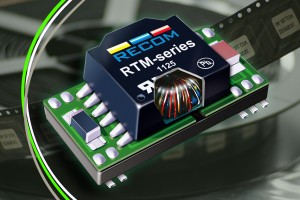

The machine-wound cores are, for example, used in encased SMD transformers found in RECOM‘s flat open-frame converters of the RAM, RAZ and RTM series, the first mini converters on the market that are produced in a fully automated process.

In addition, the transformers are now also used in the recently launched 1W R1SE converter.

A coin with six sides

Efficient production is only one side of the coin. The other side is enhanced development. We all know that quality cannot just be packed into a product. It must be part and parcel of the development process. Our coin has therefore not just two sides, but six, which actually makes it a cube. Apart from innovative development and efficient production, a global player must also meet the highest standards as regards quality assurance & certification; distribution & logistics; support & advice as well as social responsibility for the benefit of its employees and the environment.

A visit to the development department located in Gmunden, Austria, reveals the advanced technology and skills brought together by RECOM. A team of twenty engineers and technicians are working on new technological solutions and innovative products. The actual product engineering department is, however, located close to the production facilities in Taiwan.

“This division only works because we have the necessary communication capabilities,” explains Karsten Bier. It ensures, however, that the strategic know-how that is vital for the success of the company remains at its headquarters. RECOM obviously does not want to make it too easy for people who want to copy its products.

Another, equally important distinct feature of the RECOM approach is the company’s internal environmental laboratory where new products are thoroughly tested and examined at their prototype stage. The lab uses HALT (Highly Accelerated Life Test) and HASS (Highly Accelerated Stress Screening) tests to identify any weaknesses at the earliest possible moment so that they can be eliminated prior to serial production.

Another aspect that is tested here is the electromagnetic compatibility (EMC) of a product – a particularly crucial feature for the certification of converter modules. Until now, some of the tests are being performed by an external lab, which tends to lead to long delays. However, RECOM plans to establish its own EMI laboratory in 2013, and to make this facility available to customers and university faculties.

In addition, RECOM provides its customers with a detailed certification documentation, such as CB reports, which greatly facilitates the certification procedure that customers might need to undertake themselves. Such a service is today only available from a few renowned manufacturers. “Companies who essentially just put their label onto products from low-cost suppliers cannot offer this,” emphasises Karsten Bier.

Large corporations now perform routine factory audits as part of their QA system, and RECOM is often identified as the preferred supplier. “We provide our clients with all relevant documentation of our processes and appreciate any suggestions that help us reduce the failure rate to the ultimate target of zero percent,” explains Karsten Bier.

For many well-known companies in Europe, social responsibility has become a hot topic, especially in connection with products made in Taiwan. The SA8000 guidelines demand fair wages and action against child labour. RECOM has already successfully completed a number of in-house SA8000 audits, and is committed to full compliance with the guidelines. Most Chinese competitors are not yet concerned about social accountability, which gives RECOM a distinct advantage when dealing with companies in Europe and the USA.

Close to customers at a global level

RECOM products can be found in the product lists of virtually all large distributors, and sample batches of all standard series can be shipped to any location in the world within 48 hours. The company operates branch offices or qualified agencies in nearly all industrial countries around the globe. “Cooperation with customers begins well before the first modules are sold,” says Karsten Bier.

“Both new and existing customers can rely on a team of application engineers who will help them to find the best possible solution for their requirements.” RECOM is not interested in making a few quick bucks but wants to establish long-term partnerships with all its customers. This is particularly important when it comes to voltage converters, as these parts are normally integrated at a most critical point in the customers’ devices and thus become a vital component of the overall product.

“Customers can rest assured that we will not turn our back if they experience problems, for example in connection with new RoHS 6/6 soldering processes,” explains Karsten Bier, referring to an issue that affected practically all suppliers of voltage converters in the recent past.

Modular voltage converters continue to gain ground, as more and more customers want to save themselves the cost, time and uncertainty of certifying their own developments. As many development departments have only limited experience in handling electromagnetic materials, companies prefer fully certified products the moment insulation becomes a major issue. From discussions with such customers, RECOM has already gained many more ideas for new products than it can currently develop.

As an established manufacturer, RECOM will continue to expand its global business, facing up to the challenges posed by Chinese suppliers. In early 2014, the company will take its next major step towards a successful future by relocating its headquarters in Gmunden to a new building.

Marco Peretta

Contenuti correlati

-

RECOM introduce nuovi convertitori AC/DC da 4 W

La serie RAC04NE-K di convertitori AC/DC incapsulati realizzata da RECOM offre una potenza nominale di 4W continui senza derating sull’intero intervallo di ingresso da 100VAC a 277VAC nominali e da -40 °C a +80 °C, mentre quella...

-

Il driver LED ‘Fit and forget’ di RECOM

RACV22-24SW è un driver LED a tensione costante, con ingresso AC, di RECOM. Questo componenti da 22W è stato progettato specificamente per l’uso ferroviario. Il design robusto, l’elevato valore di sovratensione in ingresso, le funzioni di protezione...

-

I nuovi moduli per gate drive di RECOM

Una nuova gamma di moduli di alimentazione isolati di RECOM offre una soluzione economica e ad alte prestazioni per applicazioni di gate drive in un compatto package SSOP SMD a 36pin (misura 12.83×7.5×3.55mm). I moduli isolati hanno...

-

RECOM: convertitori da 2W e 4W per il medicale

Le nuove serie di convertitori DC/DC REM2A, da 2W nominali, e la REM4A, da 4W, di RECOM offrono un isolamento rinforzato a 5kVAC/1 min e sono classificate 2MOPP a 250VAC con creepage e clearance di oltre 8mm....

-

RECOM amplia l’offerta di prodotti di fascia alta

Con l’acquisizione di LECO, RECOM può offrire una serie di nuove soluzioni, sia custom che standard, per la conversione di potenza per i mercati di fascia alta. LECO è un’azienda specializzata nella progettazione e produzione di soluzioni...

-

RECOM presenta una serie di alimentatori AC/DC da 3W

La serie RAC03-K/SMT di RECOM è composta da alimentatori AC/DC con un’uscita di 3W a 3.3, 5, 12, 15, 18 o 24VDC da un ingresso AC universale da 85 a 265VAC (da 120 a 370VDC). Il package...

-

RECOM: alimentatori AC/DC da 15W formato open frame e DIN rail

RECOM ha aggiunto alla sua offerta una nuova gamma di alimentatori AC/DC. La serie RACM15E-K offre una potenza fino a 15W per tensioni di ingresso da 80 a 275VAC ed è disponibile in due formati meccanici: una...

-

RECOM: nuovi alimentatori AC/DC per guide DIN

RECOM ha realizzato la serie di alimentatori AC/DC REDIIN. Sono unità per guide DIN con ingresso universale 90-264V e potenze di uscita nominali di 120W, 240W e 480W. I prodotti raggiungono un’efficienza fino al 93,5% nel formato...

-

I nuovi alimentatori incapsulati RECOM da 16W

RECOM ha aggiunto alla sua gamma di alimentatori AC/DC dei nuovi componenti con potenza nominale di 16W. Realizzata per una facile integrazione in qualsiasi sistema, la serie RACM16E-K/277 è caratterizzata da dimensioni compatte e un’ampia gamma di...

-

I nuovi regolatori buck compatti e versatili di RECOM

RECOM ha realizzato una nuova gamma di regolatori buck, incapsulati in package LGA e QFN, con correnti nominali di uscita di 1, 3, 10 e 20A. Il modello RPL-1.0 è fornito in un footprint LGA di 3...